This is only the start of the story i’m still writing the rest! 🙂 check back soon!

It all started with a Grandma's shopping trolley.

It was a Sunday morning, my wife and I are having breakfast and figuring i’d just rip the bandaid off I blurted out ‘i’m going to build a race car’…. gave that a few seconds to sink in and then followed up with ‘now hear me out’.

After convincing my beautiful wife that I would build the car to the best safety standards I could afford (she’s an ICU nurse and sees the worst of everything) and that this car would be built slowly over a year or two and the costs would be spread out, she was on board.. mostly.

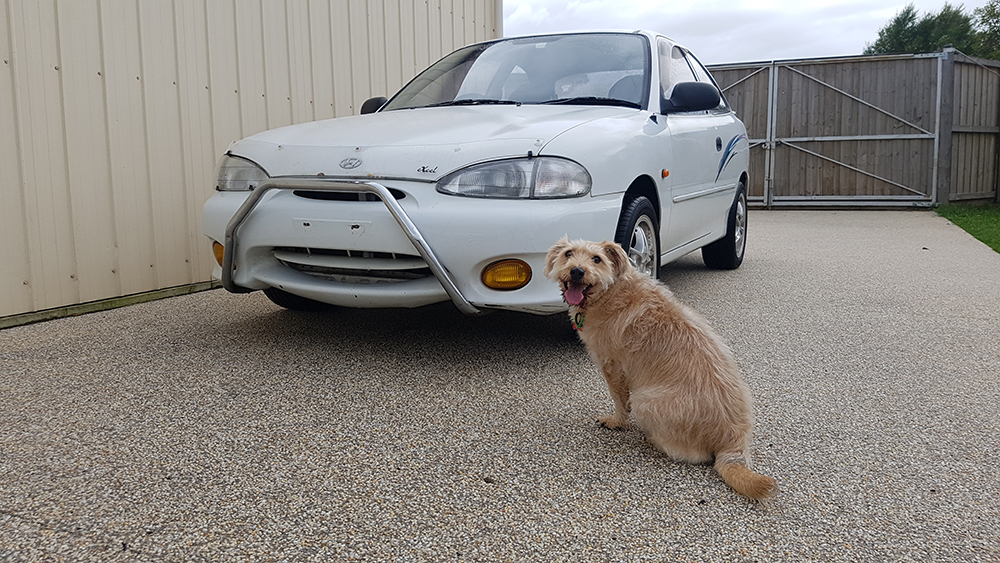

3 days later we rock up at some dudes house to look at a 99 excel he has stashed out the back, it was his mum’s car who is now in a retirement home and can’t drive anymore.

The car was covered in moss and grime and the battery was cactus. We jump started the little guy and it started up no problem, he did warn me there was a weird noise when driving it and after a spin up and down the street i figured it was the throw away bearing on the clutch, no worries as i’ll be putting a better clutch in it anyway.

An hour later i had a hire trailer hooked up to the volvo, parted ways with $600 and i was the proud owner of a ‘race car’.

Removing the yuck.

So it turns out that noise wasn’t a throw away bearing but the main bearings in the gearbox.. boo, with a quick trip to pick a part I releaved another excel of it’s gearbox and got our guy up and running. Although the car was in really good condition, no rust, very few scratches or marks i fear the service intervals may have been quite long, I bought a bunch of cheap oil on sale and did 4 flushes, the picture in the slides above was the oil after the 3rd flush with the car only running for 10 minutes!

With a new clutch and gearbox in it was time to make this bad boy more racey, we borrowed the welding skills of one of my dad’s mates to weld in some rails to the floor so we could mount our racing seat, for the first time this thing was starting to feel a little bit like a race car 🙂

All the small things...

With a good base to start with it’s time to fix everything else, suspension bushes, moving the battery, a racey steering wheel and quick release and all the other things that make a car into a race car!

With all that done it was time to paint, our family already has two white cars and white is boring so i decided to go with a custom baby blue which is now fondly refered to as ‘Nugget Blue’.

My Dad’s shed was a bloody mess with blue dust everywhere but the car was painted and looking the part.

Putting it in a cage.

With the car somewhat ready to roll it was time to work on safety, i took the car to my mate Rob at RG Customs, he’s a wealth of knowledge and skill when it comes to fabrication, he cut his teeth at Garry Rodgers motorsport building cages for legends such as Scott Mclaughlin and now i was lucky enough for him to build a cage for my little excel!.

Rob did an incredible job with the cage, i’ts an absolute work of art and made me feel more comfortable about pushing this car to it’s limits and hopefully eventually getting it to the mountain itself.. Bathurst.